Application of MVR evaporation process in wastewater treatment

- Release date: 2025-11-20 15:52:22

- Author: 鸿泰华瑞

- Reading: 124

- Keywords: MVR evaporation

This paper focuses on the application of MVR evaporation process in evaporative concentrated wastewater treatment, the secondary vapor generated by evaporation enters the evaporation system after compression, and the concentrate is crystallized by the three-effect mixed flow forced circulation evaporator, so that the salt is supersaturated and crystallized, and the separated mother liquor is returned to the evaporation crystallization, and the separated crystals enter the centrifugal drying packaging system for weighing and packaging. MVR evaporation utilizes the energy of secondary steam, reducing energy consumption.

1. MVR evaporation process

MVR evaporation process mainly uses the secondary steam energy generated by evaporation, thereby reducing the demand for external energy, and is a very energy-saving technology. In the process of multi-effect evaporation, the secondary steam of the evaporator cannot be directly used as an energy source, but is realized through multiple heat sources. Steam injection pumps can usually compress part of the steam, and the MVR evaporation process can compress all the secondary steam, so as to improve the steam compression efficiency, improve the heat energy reserve, and transfer it to the heating chamber for secondary evaporation, so that the thermal energy circulation system is formed, and the condensate generated by the condensation of the evaporated water during operation can be eliminated after heating the raw materials.

In the use of MVR evaporation process, due to the full use of latent heat energy of secondary steam, MVR evaporation process has the following advantages compared with traditional evaporators:

First, the energy saving effect is remarkable. According to relevant surveys, the energy consumption of MVR evaporators is only 30% of that of ordinary evaporators;

second, there is no need to use other energy sources, only enough electrical energy needs to be provided to ensure the normal evaporation process;

Third, since the MVR evaporation system includes a heater and secondary vapor condensation, there is no need for additional condensers and no cooling cycles;

fourth, the area occupied is small, the dependence on labor is low, and there are few supporting public works projects;

Fifth, the application is very safe and reliable, and the whole system can form configuration control and can be automated.

Sixth, the temperature can be freely set between 15-100 °C, which has strong adaptability to some heat-sensitive materials, and does not require freezing cooling water under low temperature evaporation conditions, reducing engineering investment.

2. Practical analysis of MVR evaporator application

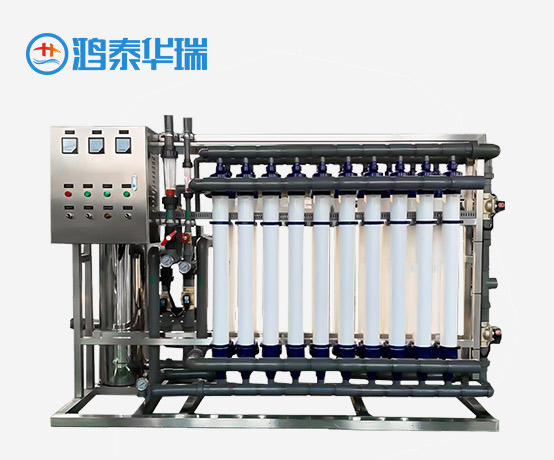

(1) Pretreatment softening system

The wastewater is softened by the pretreatment system, which can be softened by the glaubernite-lime-flue gas method to remove cations that are prone to scaling. In practical application, firstly, after adding lime milk and mirabilite, enter the centrifuge to obtain the centrifugal separated dissolution solution, and adjust the PH value according to the actual requirements of the entire MVR evaporation system and wastewater treatment. Secondly, after the above preliminary treatment is completed, the flue gas is used to react with wastewater impurities to generate precipitate, remove calcium ions and other precipitates, and filter through the ceramic membrane, the mass fraction of suspended solids in the filtered soft water will be significantly reduced, usually below 0.001%. After softening treatment, the mass fraction of sediment and calcium ions in the wastewater is greatly reduced, and the wastewater entering the evaporator system is mainly sodium sulfate, sodium chloride and other salts, which can avoid the problem of scaling during concentration and crystallization of the entire evaporation system. This method usually requires cleaning the system once a year.

(2) Evaporation-crystallization system

The MVR evaporator system and the three-effect mixed flow forced circulation evaporation crystallization subsystem in the crystallization stage are adopted, and the scale inhibitor is added after the wastewater enters the MVR conditioning tank, which can further alleviate the problem of scaling in the heat exchanger tube, and reserve enough space in the conditioning tank to ensure that the mixture fully reacts, and separate the gas and other non-condensable gases through the deaerator, so as to ensure the steam heat transfer efficiency and improve the conversion rate. The evaporator is capable of evaporating 80% of the water, which is not only efficient, low energy consumption, but also occupies a very small area. It can meet the temperature requirements of MVR evaporators to the greatest extent and improve the safety of the entire system operation. Relevant studies have shown that when the evaporation and concentration of soft wastewater is 7 times, its boiling point should be increased by 3°C. In order to reduce the operating cost of the MVR evaporation system, a set of MVR centrifugal compressor evaporators and a set of three-effect mixed-flow forced circulation evaporators can be used together. According to the process application practice, before the mass concentration of salt in soft wastewater is 20%, the boiling point is increased within 3 °C, the MVR centrifugal compressor is used to evaporate the secondary steam after pressurization, the energy consumption is 20 (kw•h)/t, the evaporation temperature is 90 °C, and the secondary steam temperature is 88 °C. This increases efficiency and reduces costs.

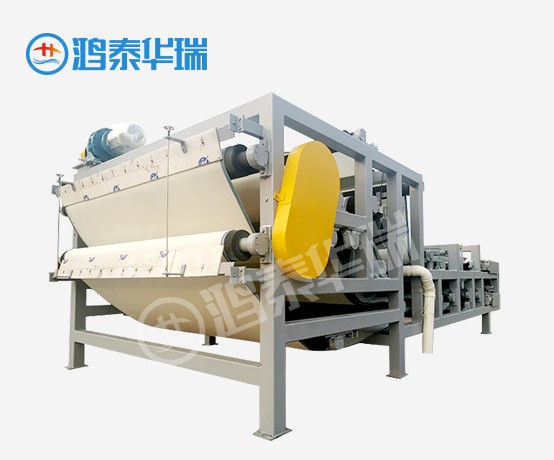

(3) Centrifugal drying packaging system

Centrifugal, drying, packaging processes (including centrifuges, fluidized bed dryers, automatic packaging machines, etc.), the moisture content of the material separated by the centrifuge is about 5%, the moisture content of the material is too high, it needs to be dried and dehydrated, the wet material first needs to be heated in the steam heat exchanger and then transferred to the dryer, and the drying air temperature is controlled between 140°C and 150°C. The wet material is transferred to the feeder, and then evenly put into the fluidized bed mechanical rake dispersion device, which is in contact with hot air to increase the temperature of the material and carry out drying treatment. This ensures that the material is in a loose state, which in turn ensures the actual operating requirements. The crystalline salts formed after drying can be transferred to the storage bin through the belt for storage. The process is very simple in practical applications and has a high degree of automation, which can achieve the purpose of turning waste into treasure.

3. Conclusion

In summary, wastewater treatment is one of the key issues in the industrial field today, in order to ensure the effectiveness and economy of wastewater treatment, the use of MVR evaporation process is of great significance, which can not only reduce energy consumption and save operating costs, but also can dry and store evaporate, realize the recovery and reuse of resources, and achieve sustainable economic development.