- release date: 2022-08-15 02:04:00

- author: Hongtai Huairui

- Reading: 4969

key words: Wastewater treatment, printing and dyeing wastewater

Hongtai Huarui Technology Group welcomes your visit. We have been dedicated to the environmental protection and governance industry for over a decade! We look forward to a cooperation with you!

key words: Wastewater treatment, printing and dyeing wastewater

project overview

The company is a Taiwanese-owned enterprise, mainly focusing on cotton products, as well as some polyester products. The company's production wastewater meets national emission standards after being treated by the original wastewater treatment station. As the production scale of the company continues to expand, the amount of wastewater produced is also increasing day by day. To this end, it is necessary to build a new printing and dyeing wastewater reuse and treatment project to deeply treat the wastewater after the original wastewater treatment station reaches the standard. The treated effluent is used for workshop production, which not only realizes the recycling of water resources, but also brings certain economic benefits. The company's production workshop mainly uses reactive dyes and a small amount of disperse dyes. Commonly used chemicals are sodium sulfate, ammonium sulfate, sulfuric acid, sodium carbonate, carriers (various organic compounds), surfactants, etc. The resulting wastewater contains pollutants such as dyes, slurries, additives, oils, alkalis, fiber impurities, sand substances, and inorganic salts. Moreover, it has the characteristics of large amount of water, high organic pollutant content, high alkalinity, and large water quality changes. It is one of the industrial wastewater that is difficult to treat.

The scale of the reuse water treatment project is 3000m3/d and adopts a combined process of "high-efficiency biological aerated filter + coagulation air flotation + ultrafiltration + ozone/activated carbon filtration + resin exchange, and the effluent meets the company's workshop reuse water requirements. The project covers a total area of about 220m2 and has a total installed capacity of 182.96kW. The operating cost of ordinary reuse water is about 1.26 yuan/m3wastewater (excluding depreciation), and the operating cost of high-quality reuse water is 1.53 yuan/m3wastewater (excluding depreciation).

The project uses integrated reclaimed water reuse and treatment equipment with independent intellectual property rights, which integrates high-efficiency coagulation, air flotation, oxidation and filtration. The effluent water can stably meet the requirements of workshop reuse water.

Design basis

(1) Various relevant basic information provided by the builder (water quality, water quantity, water reuse requirements, etc.);

(2) Water sample analysis data obtained from on-site survey:

(3) Water quality standards for textile printing and dyeing processes:

(4) "Water Pollutant Discharge Standard for Imitation Dyeing and Finishing Industry" (GB4287-2012);

(5) Comprehensive Sewage Discharge Standard (GB8978-1996);

(6) Other relevant standards.

Design principles

(1) Conscientiously implement the national guidelines and policies on environmental protection, so that the design complies with relevant national regulations, norms and standards:

(2) Comprehensively considering the characteristics of wastewater inlet and outlet water quality and quantity, the selected process should be technologically advanced, stable and reliable, economically reasonable, safe and applicable:

(3) Properly treat and dispose of sludge and scum generated during wastewater reuse treatment to avoid secondary pollution;

(4) The automatic control system of the wastewater reuse treatment system should be convenient to manage, safe and reliable, economical and practical:

(5) The layout of the wastewater reuse treatment system should strive to be compact, reduce the footprint and investment, and the elevation layout should adopt a three-dimensional layout as much as possible to make full use of the underground space.

(6) Design in strict accordance with the conditions defined in the bidding documents to adapt to the actual situation of the project.

Source of pollution

(1) Production sewage generated by the plant;

(2) Flushing wastewater on the ground of the production site;

(3) Domestic sewage.

Processing technology

The optimization of the reuse water treatment design includes both water quality and water quantity optimization. Water quality optimization refers to the in-depth treatment of wastewater through the effective combination of different treatment technologies or different process units to make the effluent quality meet the requirements of reuse. Due to the large difference in the water quality of reused water required by the construction unit, this design first optimizes the water quality of the wastewater with the largest amount of wastewater, and then appropriately supplements the water volume with higher requirements. Water optimization means that enterprises should choose a more economical reuse method according to their own situation. Practice has proved that the water quality of the reused water treated by the above combination scheme can fully meet the water requirements of the workshop. If with the improvement of process technology, better quality reuse water is required, if fresh water can be mixed with the quantitative ratio of reused water.

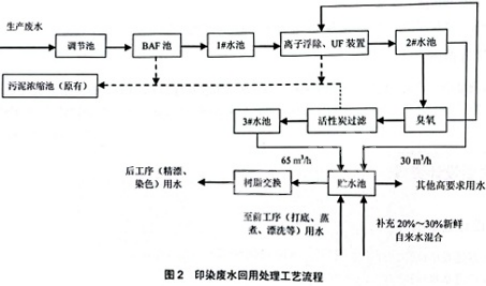

The wastewater reuse treatment process consists of six parts: pretreatment system, ion flotation reaction system, ultrafiltration treatment system, ozone/activated carbon system and resin exchange system, and the process flow is shown in Figure 2.

Handling indicators

According to the information provided by the construction unit, the design water volume is 3000m3/d.

The design influent water quality indicators are shown in Table 1.

Table 1 Design wastewater influent water quality

|

project |

COD/(mg/L) |

Chromaticity (dilution) |

pH |

SS/(mg/L) |

Total hardness/(mg/L) |

|

Influent water quality |

≤110~120 |

≤50 |

7.4~6.8 |

80 |

50 |

3.2 Design effluent quality

Due to the complexity of the printing and dyeing process itself and the difference in the water quality requirements of process water, there is currently no unified standard for the reuse water quality standard of Yinduo wastewater in China, so the reuse water quality standard is determined according to the specific production requirements of the workshop of the enterprise, and the specific water quality indicators are shown in Table 2.

Table 2 Water quality requirements for reuse water in production workshops

|

project |

COD/(mg/L) |

Chromaticity (dilution) |

pH |

SS/(mg/L) |

Total hardness/(mg/L) |

|

The quality of the effluent |

≤50 |

≤15 |

6.5~8.5 |

Invisible to the naked eye |

250 |

Previous Article:No more

Next Article:Circulating cooling water treatment proj...

The content you might be interested in

Environmental Protection Information

Selected Recommendations

Recommended Products