- release date: 2022-08-30 19:17:49

- author: Hongtai Huairui

- Reading: 4206

key words: Paint painting, organic waste gas

Hongtai Huarui Technology Group welcomes your visit. We have been dedicated to the environmental protection and governance industry for over a decade! We look forward to a cooperation with you!

key words: Paint painting, organic waste gas

project overview

As a process design case for the organic waste gas treatment system of a paint shop, paint waste gas is one of the main sources of pollution to the atmospheric environment. Because of its high toxicity, it poses a very serious hazard to human health, especially benzenes and polycyclic aromatic hydrocarbons. They invade human nerve, respiratory, blood and reproductive systems, causing dizziness, nausea, and at worst, aplastic anemia, leukemia, and cancer that threaten life, so there is an urgent need for treatment.

This device adopts the latest process design, namely dry filtration + activated carbon adsorption and desorption + catalytic combustion, which has a very significant effect in controlling VOCs pollution and has good practical value for environmental protection, labor protection and human health protection.

Design basis

(1) Exhaust gas volume: 30000Nm3/h;

(2) Operating temperature: normal temperature;

(3) Exhaust gas conveying pressure: 3000Pa;

(4) Treatment efficiency: 80%;

(5) Inlet concentration: ≤200mg/m3

(6) Outlet concentration: ≤50mg/m3

Design principles

When the gas molecules move to the solid surface, due to the interaction between the gas molecules and the solid surface molecules, the gas molecules temporarily stay on the solid surface, resulting in an increase in the concentration of gas molecules on the solid surface, which is called the adsorption of gas on the solid surface. The adsorbed substance is called the adsorbent, and the solid substance of the adsorbent is called the adsorbent. The activated carbon adsorption method is a method of using activated carbon as an adsorbent to adsorb the organic compounds in the exhaust gas to the surface of the solid phase for adsorption and concentration, so as to purify the exhaust gas.

The large air volume and low concentration organic waste gas are removed by the front-end primary three-stage dry filter to remove the paint mist and dust, and then pass through the activated carbon adsorption bed, fully contact with the honeycomb activated carbon, and then desorption and regeneration are converted into small air volume and high concentration organic waste gas. This part of the gas enters the catalytic combustion oxidation equipment at the back end for oxidation reaction, so that the volatile organic compounds in the exhaust gas are oxidized and decomposed into carbon dioxide and water in the catalytic oxidation chamber, and the heat is released. At the same time, the system uses part of the hot gas to regenerate the activated carbon to ensure that the activated carbon is reused.

Source of pollution

Organic exhaust gases from the paint booth.

Processing technology

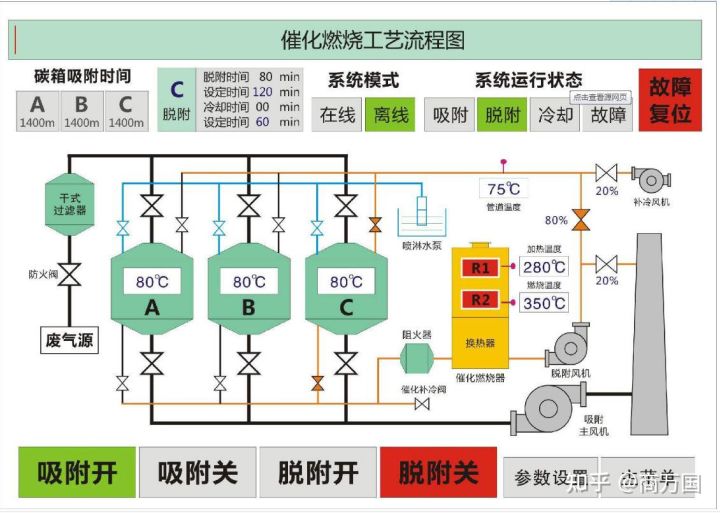

The working process of this device can be divided into four stages: exhaust gas collection stage, primary dry filtration stage, activated carbon adsorption stage and activated carbon desorption and regeneration stage.

Exhaust gas collection stage:

A special exhaust gas collection hood and pipeline system are set up in the paint booth to collect the exhaust gas centrally.

Primary dry filtration stage

The exhaust gas from the painting booth first enters the primary dry filter for pretreatment, and after the three-stage filtration of the primary dry filter, the particulate matter in the organic exhaust gas is intercepted, which provides strong conditions for the subsequent activated carbon adsorption process and ensures the service life of the activated carbon.

Activated carbon adsorption process:

The organic exhaust gas after the primary dry filter enters the activated carbon adsorption device. When the organic exhaust gas passes through the activated carbon layer, the organic components in the organic exhaust gas are attracted to the surface of the activated carbon and concentrated on it. The organic components are thus separated from the other components, and the other components (clean gases) are evacuated by the fan.

Activated carbon desorption process:

Activated carbon is used for a period of time, after adsorbing a certain amount of solvent, it will reduce or lose its adsorption capacity, at this time activated carbon needs to be desorbed and regenerated, and the activated carbon restores its adsorption capacity after regeneration, and can continue to be used. When regenerating, start the power supply of the preheating chamber of the catalytic combustion device, preheat the air, send the preheated gas to the adsorption box, after the activated carbon in the box is heated, the solvent adsorbed by the activated carbon evaporates, the solvent is sent to the catalytic combustion chamber through the fan for combustion, decomposed to form CO2 and H2O and other hot air, part of the hot air returns to the activated carbon adsorption box to continue to heat the activated carbon, the other part is emptied, and the activated carbon can be regenerated by circulating the hot air many times.

The main features of this process:

(1) Good production environment and no pollution.

(2) The process equipment has strong reliability, small faults and maintenance volumes, low maintenance costs, and reduces the workload of maintenance personnel.

(3) Due to the high degree of automation, there are few operators and low labor intensity.

(4) It can fully recover waste heat and save energy.

(5) The system investment is small and the operating cost is low.

The layout of the general drawing of the organic waste gas treatment process

(1) Primary dry filter: arranged in the factory. This scheme uses one DN1000 primary dry filter;

(2) Activated carbon adsorption box: arranged in the factory. This scheme uses 3 activated carbon adsorption boxes, and the operation mode is: 2 opens and 1 standby;

(3) Catalytic burner: arranged in the plant. This scheme uses a 2500Nm3/h catalytic burner;

(4) Chimney: Arranged outdoors in the open air. The chimney design diameter is DN1000, and the height is 16 meters;

(5) Main exhaust fan: arranged in the factory. Equipped with 1 exhaust fan. Model: 4-72-9 Right 45°, flow rate 35700Nm3/h, full voltage 2914Pa, motor: 45KW;

(6) Detachment fan: arranged in the factory. Equipped with 1 desorption fan. Model: 6-35-4 right 0°, flow rate 2314Nm3/h, full voltage 2512Pa, motor: 3KW;

(7) Replenishment air conditioner: arranged in the factory. Equipped with 1 supplementary air conditioner. Model: 4-72-2.8 right 0°, flow rate 1141Nm3/h, full voltage 963Pa, motor: 1.5KW;

(8) The treatment plant of organic waste gas should be arranged separately from other production plants, and the spacing should comply with the relevant provisions of the current national standard "Fire Prevention in Building Design";

(9) The fire lane in the treatment area of organic waste gas shall comply with the relevant provisions of the current national standard "Fire Protection Code for Building Design";

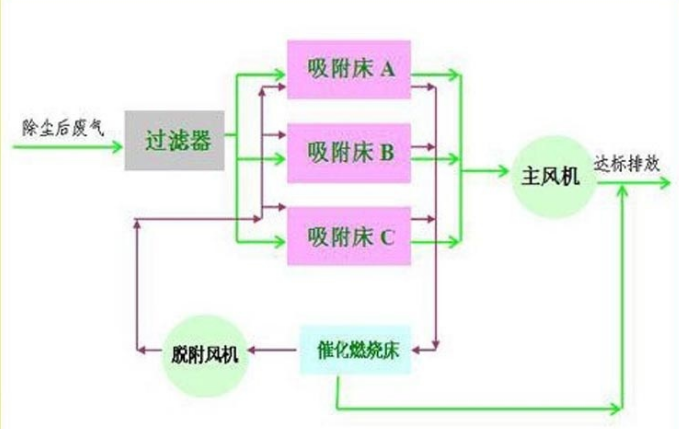

(10) The layout of the general drawing of the organic waste gas treatment process, please refer to the general diagram of the organic waste gas treatment process in Figure 4-1 for details.

Figure 4-1 General diagram of organic waste gas treatment process

Handling indicators

(1) Wide range of application. Catalytic burners can treat almost all hydrocarbon organic exhaust gases and odorous gases. For the low-concentration, multi-component, and non-recyclable exhaust gas emitted by organic chemicals, coatings, insulation materials and other industries, the adsorption-catalytic burner method has a better treatment effect.

(2) High treatment efficiency and no secondary pollution. The purification rate of organic waste gas treated by catalytic oxidation method is generally more than 95%, and the final products are harmless CO2 and H2O, and due to the low combustion temperature, the formation of NOx can be greatly reduced, so it will not cause secondary pollution.

(3) The treatment of organic mixed waste gas is controlled by the automatic control system, with simple operation process, simple start-up and shutdown, low failure rate, long operation cycle, and good safety.

conclusion

With the increasing national requirements and efforts for environmental protection, the treatment of industrial organic waste gases (VOCs) has developed rapidly. There are also several more mature treatment processes on the market. The process design described in this paper adopts dry filtration + activated carbon adsorption and desorption + catalytic combustion. The design process is mainly for the treatment of VOCs with large air volume, low concentration, and no need for recovery. This process has obvious effects and advantages in the treatment of VOCs pollution, and has good practical value for environmental protection and human health. This technology has low investment cost, low operating cost, simple operation and long service life, which is more conducive to the promotion and application in the field of VOCs treatment technology in factory painting workshops.

Previous Article:Breeding wastewater treatment and reclai...

Next Article:Design of wastewater treatment station f...

Environmental Protection Information