Analysis of Price Factors for Industrial Wastewater Treatment Equipment: From Initial Investment to Operating Costs

- release date: 2026-01-13 13:54:02

- author: Hongtai Huairui

- Reading: 354

- key words: Industrial Wastewater、 Treatment Equipment

With increasingly stringent global environmental regulations and the continuous tightening of policies such as carbon border taxes, industrial enterprises face a dual dilemma of compliance and cost: failing to upgrade wastewater treatment equipment risks substantial fines and production shutdowns, while investing in upgrades is often hindered by high initial investment, uncontrollable operational costs, and technology mismatch. Especially for small and medium-sized enterprises (SMEs) in sectors like chemicals, pharmaceuticals, electronics, and food processing, precisely understanding the cost composition of wastewater treatment equipment and achieving cost minimization under compliance constraints has become crucial for survival and growth. This article deconstructs the core price factors of industrial wastewater treatment equipment from a global perspective and shares pathways for intelligent technologies to break the cost dilemma—this is precisely the core value proposition of Hongtai Huarui Technology Group Co., Ltd.

Enterprises often fall into a common misconception during equipment selection: focusing solely on the quoted price of the equipment itself. In reality, the price of industrial wastewater treatment equipment is a comprehensive cost covering its entire lifecycle, primarily consisting of two major components: initial investment and operational costs. Both are influenced by multiple factors such as technology selection, industry-specific characteristics, and regional policies. Clarifying the inherent logic of these factors is a prerequisite for enterprises to avoid investment pitfalls and achieve long-term cost reduction.

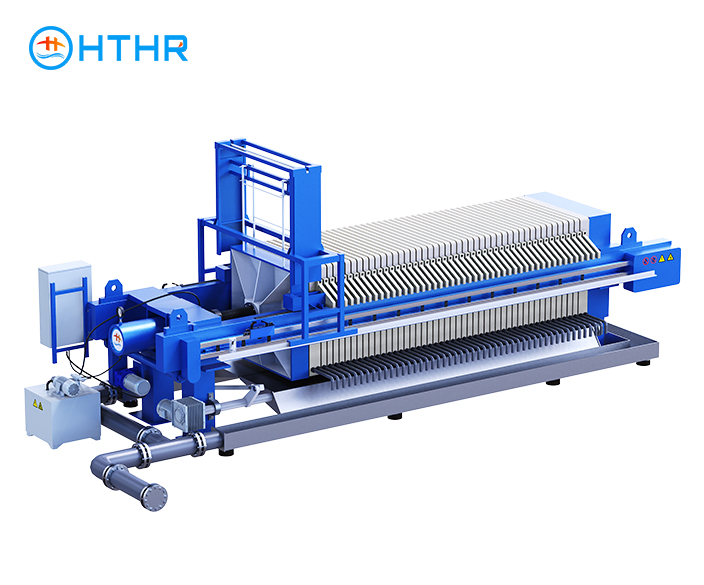

Initial Investment is the most direct cost outlay for enterprises. Its composition includes not only the equipment cost itself but also hidden costs such as supporting infrastructure construction, certification and compliance, and installation and commissioning labor. These hidden costs can account for 40%–60% of the equipment price, easily leading to budget overruns. The equipment cost itself typically constitutes 40%–60% of the total initial investment, with the specific amount depending on the technology path and equipment materials. For example: the chemical and pharmaceutical industries, treating high-concentration, high-toxicity wastewater, require combined processes like advanced oxidation and membrane concentration, with traditional equipment initial investments ranging from ¥1500 to ¥2500 per ton of water; the electronics industry, treating heavy metal wastewater, requires specialized ion exchange equipment, with 316L stainless steel material costing 2–3 times more than ordinary carbon steel equipment; the food processing industry, dealing with highly biodegradable wastewater, can use traditional biological treatment processes with an initial investment only about one-third of that for the chemical industry.

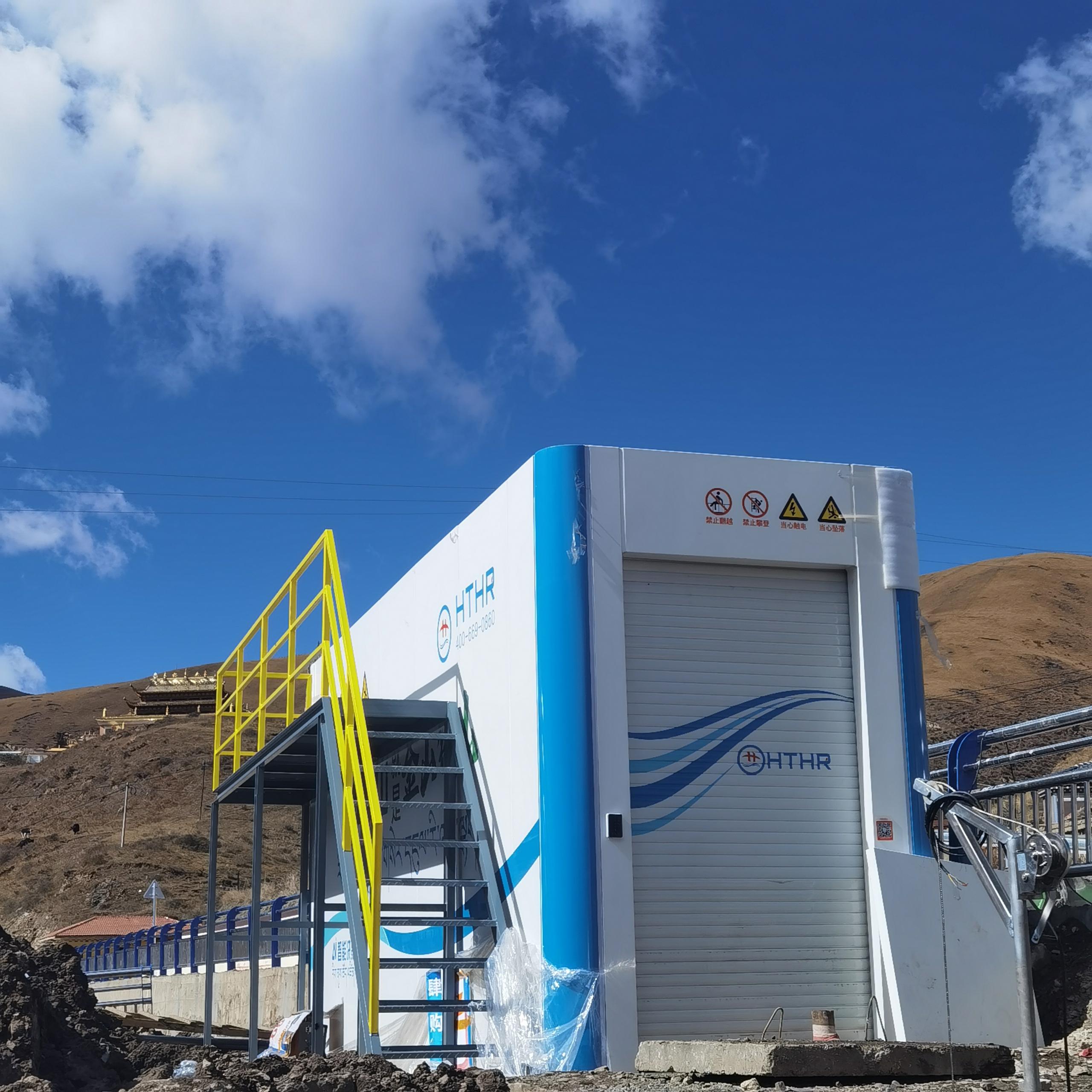

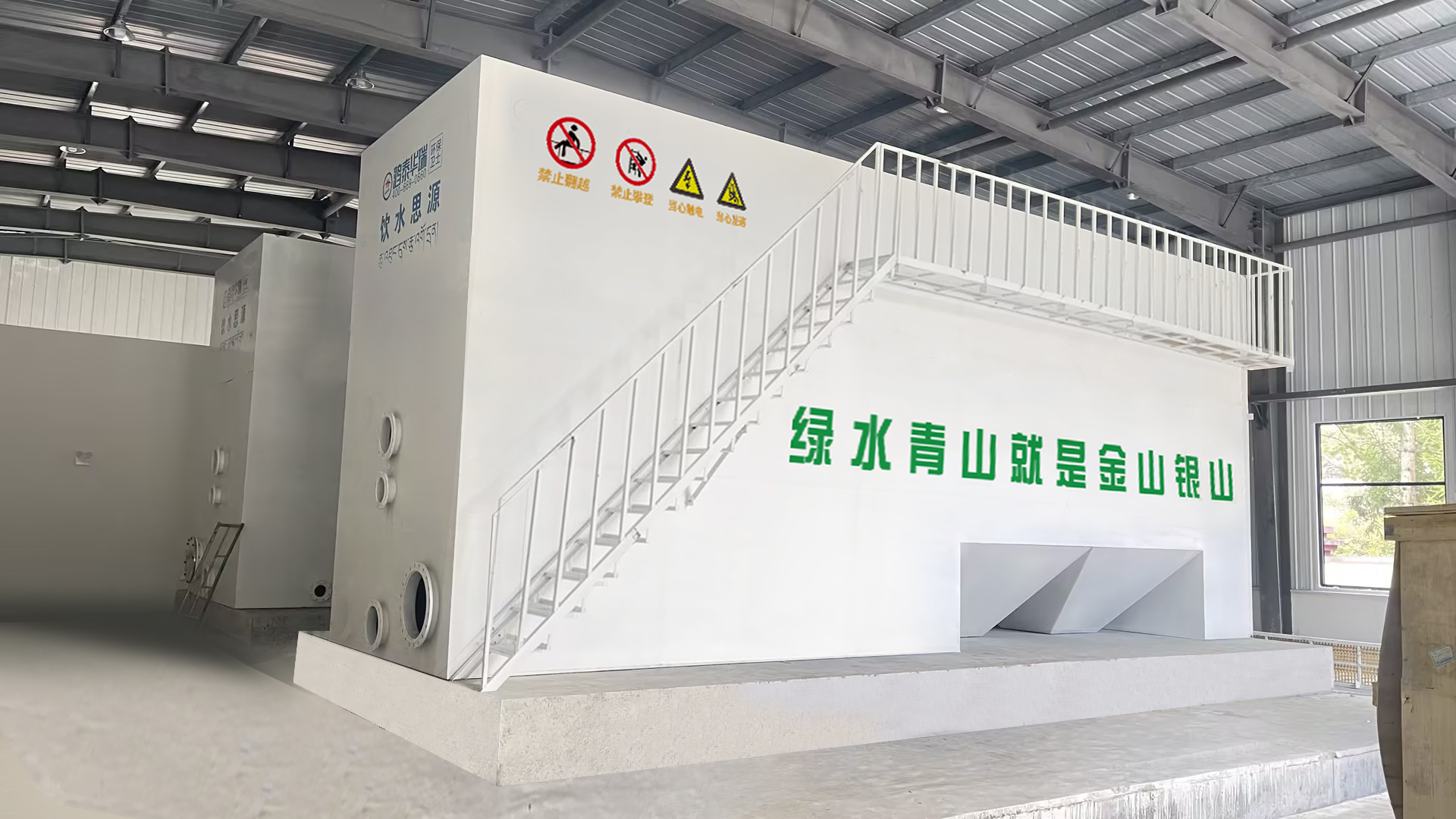

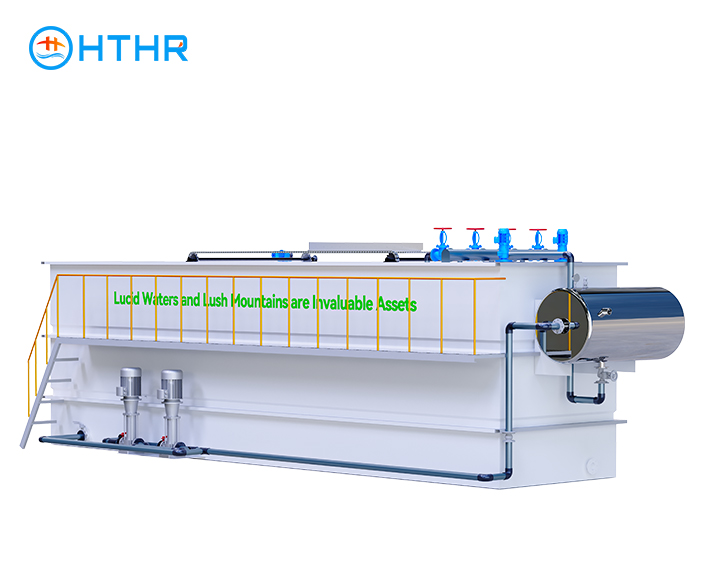

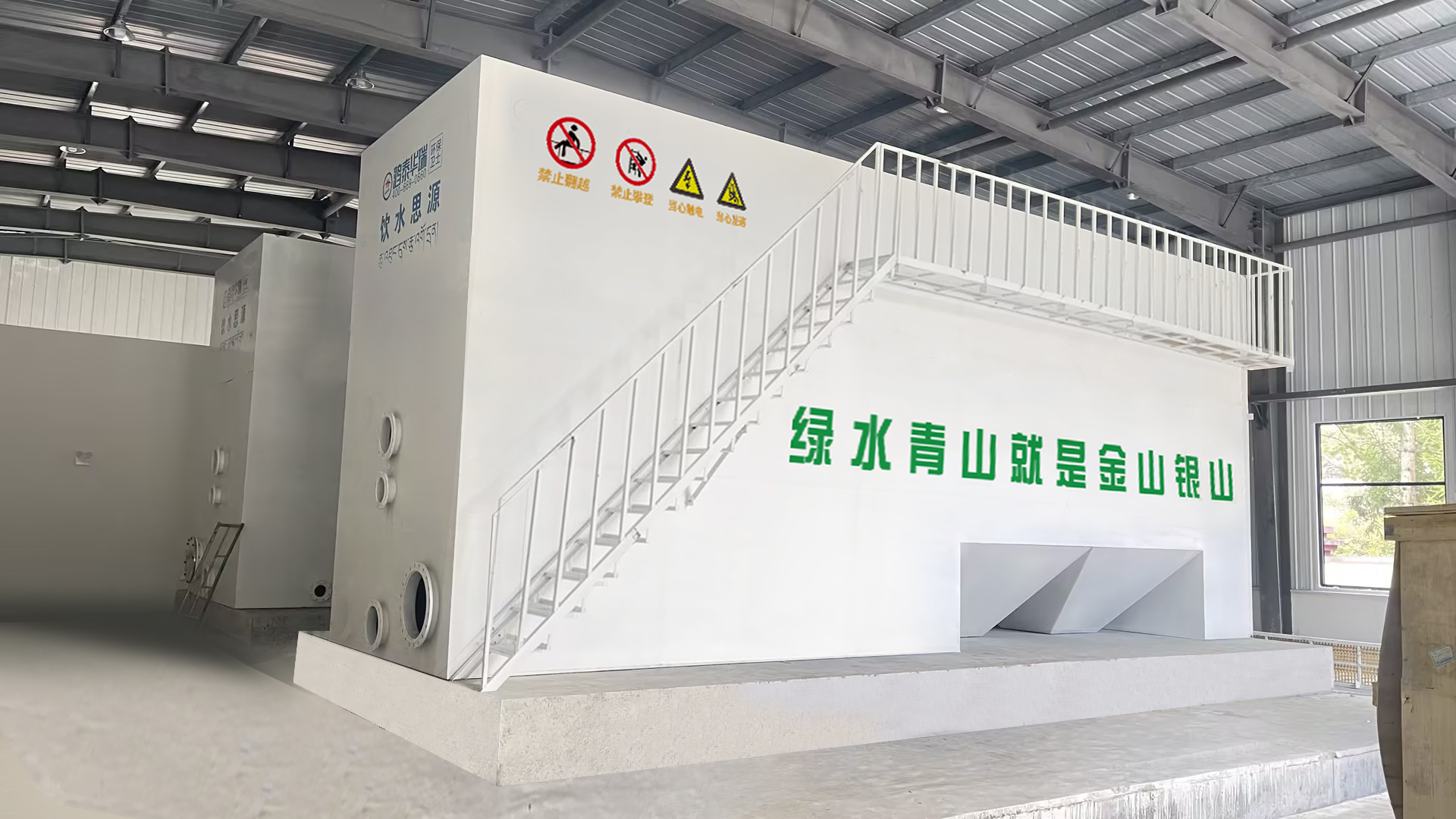

Hongtai Huarui's intelligent modular solutions redefine traditional cost logic. Driven by both "AI + Hardware," the company deeply integrates its self-developed Feihong System (FyhoneOS) with modular equipment, adaptable to the diverse treatment needs of SMEs across industries. Standardized prefabricated production reduces manufacturing costs, and equipment can be assembled on-site, shortening the construction period by over 50% and significantly saving on hidden costs like civil engineering, installation, and commissioning. This allows SMEs to adopt advanced treatment technologies without massive initial capital outlays.

Supporting Infrastructure and Certification/Compliance Costs are often overlooked: entering the EU market requires CE certification and compliance with carbon footprint traceability requirements, while the US market requires NSF certification, both adding time and financial costs. By launching on Alibaba International Station by the end of 2025, Hongtai Huarui exports its mature intelligent water treatment solutions to regions like Southeast Asia and Central/Eastern Europe, helping enterprises bypass certification barriers and reduce redundant certification investments.

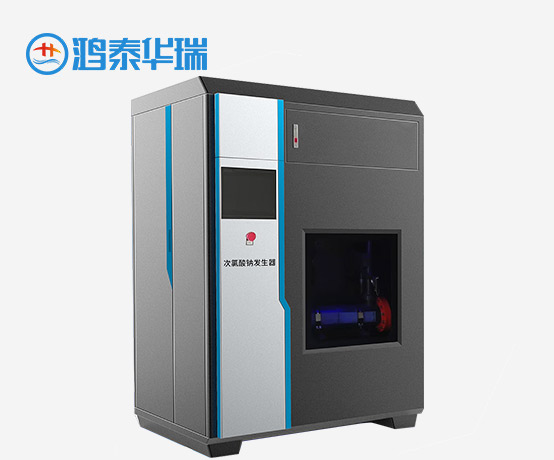

Operational Costs are the long-term "money drainers," with cumulative expenditures often exceeding the initial investment. They mainly include four components: energy consumption, chemicals, labor, and maintenance. Among these, energy consumption accounts for 40%–60%. Core components like aeration systems and pumps in traditional equipment often have high energy consumption. For instance, traditional activated sludge process equipment consumes about 0.5–1.0 kWh per ton of water, while energy consumption for advanced oxidation equipment in the chemical industry is even higher. Chemical waste is a prominent issue, with manual dosing reliant on experience often leading to 20%–50% overdosing, increasing costs and accelerating equipment corrosion. Additionally, shortages of specialized maintenance personnel, low efficiency of manual inspections, and difficulties in maintaining stable operation at remote, unattended sites further add to operational burdens.

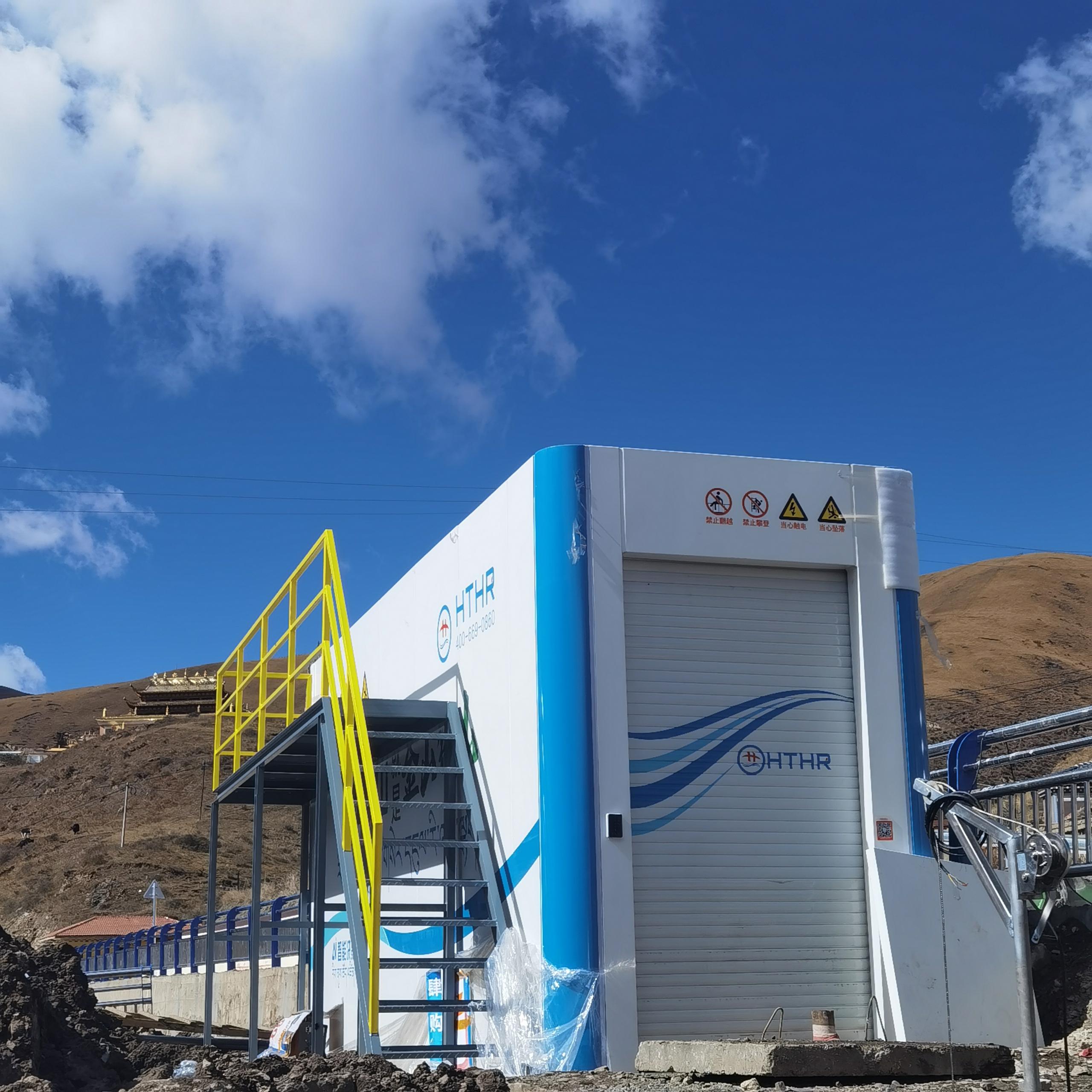

Hongtai Huarui's core Feihong System, utilizing a SARIMA + LSTM hybrid model and digital twin technology, can accurately predict water quality and quantity changes up to 8 hours in advance, with an error margin controlled within ±3 mg/L, surpassing industry averages. Based on these predictions, it enables automatic adjustment of aeration intensity, sludge recirculation ratio, and chemical dosing, reducing comprehensive energy consumption by over 30%. It supports remote monitoring via mobile APP, improving maintenance response efficiency by 60% and saving labor costs by 50%, achieving stable "low-manpower" or "unmanned" operation for dispersed small and medium-sized treatment stations.

Global Environmental Policies and Market Conditions significantly impact equipment prices and selection. For example, the EU's full implementation of the Carbon Border Adjustment Mechanism (CBAM) from 2025 requires imported equipment to submit carbon emission declarations, increasing demand for high-efficiency, low-carbon equipment, which is priced 5%–10% higher than standard equipment. Conversely, the US Inflation Reduction Act (IRA) provides tax credits for green technologies, indirectly reducing the investment cost of intelligent environmental equipment. In emerging markets like Southeast Asia and Central/Eastern Europe, SMEs demand equipment that adapts to local water quality characteristics (e.g., high salinity, low temperature) while emphasizing cost-effectiveness. Hongtai Huarui's global layout precisely matches this demand. Its equipment can adapt to different regional water conditions, and its localized service network provides 24-hour rapid response. Its intelligent solutions have been proven in practical projects both domestically and internationally, with effluent compliance rates consistently exceeding 99%, helping enterprises avoid environmental penalty risks.

The core of wastewater treatment equipment cost optimization is not choosing the option with the lowest initial unit price, but the option with the highest value over its entire lifecycle. Industries with complex wastewater like chemicals and pharmaceuticals should prioritize intelligent equipment with strong technological adaptability to avoid waste from secondary modifications. Industries like food processing can adopt combined solutions of biological treatment and intelligent control to balance cost and efficiency. Hongtai Huarui's full-chain intelligent water treatment solution, centered on "Intelligent Hardware + AI Algorithms + Precise Chemicals + Integrated Management," adapts to the diverse needs of SMEs across different industries and regions. Through intelligent whole-process control, it achieves long-term cost reduction and efficiency improvement, providing customized solutions for both new plant construction and old plant upgrades, precisely addressing enterprise pain points in compliance and cost control.

With global environmental pressures continuously rising, wastewater treatment equipment selection has become a strategic investment. Enterprises need to look beyond the surface of initial investment and recognize the composition of lifecycle costs and the value of technology. As a representative of "Intelligent Manufacturing in China," Hongtai Huarui leverages technological innovation and global expansion to bring efficient, energy-saving, and hassle-free intelligent water treatment solutions to the world. It transforms wastewater treatment from a cost burden into a core competitive advantage for enterprises' green transformation—this is the ultimate significance of equipment selection.

hthrjt2017@gmail.com

hthrjt2017@gmail.com