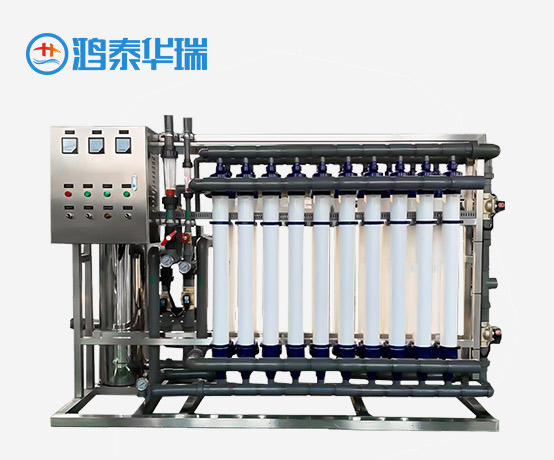

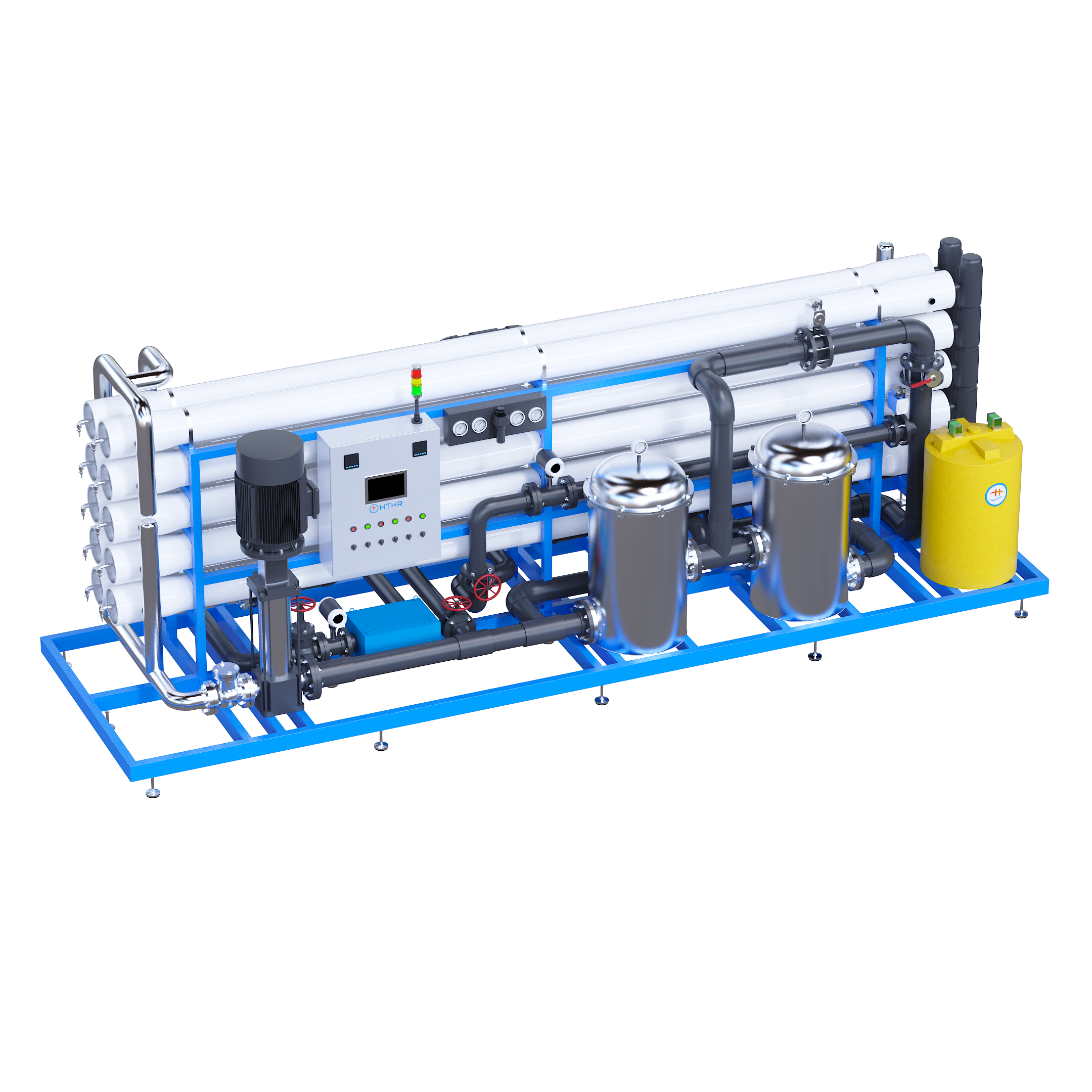

In the current era of increasing water scarcity, ultrafiltration (UF) and reverse osmosis (RO) membranes have become “core equipment” in the field of water treatment. Whether it’s seawater desalination, industrial wastewater reuse, or municipal water purification, they all rely on these technologies. The United Nations Sustainable Development Goal (SDG 6) clearly states that by 2030, everyone worldwide should have access to clean drinking water and sanitation facilities. Membrane separation technology, as an efficient water treatment solution, is one of the key supports to achieving this goal. According to an ACS Publications 2025 research report, approximately 720 million people globally are facing severe water resource pressures, and RO technology accounts for 74% of the global seawater desalination installed capacity, making it a critical technology for addressing water shortages. Additionally, both the Global Water Intelligence (GWI) and the International Water Association (IWA) are promoting the large-scale application of membrane technology in zero liquid discharge (ZLD) and water resource recycling, responding to the global call for sustainability.

However, for many industry practitioners, the frequent wear and tear of membrane elements and the high replacement costs have been ongoing headaches. According to the GWI 2025 industry white paper and market research data, membrane modules account for 30%-45% of the initial investment in water treatment systems, and the annual operation and maintenance (O&M) costs of RO systems account for 10%-14% of the total investment, with pollution control-related expenses making up over 40% of the O&M costs. In fact, to extend the lifespan of membranes, it’s not about blindly upgrading equipment or frequent replacements. The key is to adopt a maintenance strategy that aligns with cognitive principles — one that meets international sustainability goals while helping businesses reduce O&M costs by more than 20%, achieving a win-win in both ecological and economic benefits.

Many people initially fall into the misconception that membrane damage is due to quality issues, but in most cases, the root cause lies in not controlling the water quality entering the system properly. It’s like how, to avoid getting sick, one needs to take preventive measures first. To ensure the membrane’s “longevity,” the first step is to get the pretreatment right. According to the American Society for Testing and Materials (ASTM) D4189–23 standard (the globally accepted membrane feed water quality evaluation standard), the SDI (Silt Density Index) of the RO system feed water must be controlled below 3, and the turbidity must not exceed 0.5 NTU (previously 0.2 NTU was the strict standard, with 0.5 NTU being the general standard). This standard is also applicable to UF system effluent after pretreatment and is a fundamental threshold for ensuring the safe operation of membranes. It has been widely adopted by the global membrane industry.

Furthermore, the focus of pretreatment varies significantly depending on the water source, so it cannot be generalized. For municipal water sources, residual chlorine is the main “killer,” and it must be removed through activated carbon filtration or the addition of reducing agents to lower the residual chlorine to below 0.1 mg/L, otherwise, it can easily oxidize and damage the polyamide membrane. If the water is surface water, which contains a lot of organic matter and algae, the “coagulation + ultrafiltration” process combination is ideal. It can remove over 85% of pollutants like humic acid and sodium alginate, and some optimized processes can achieve more than 90%. For seawater desalination, the focus should be on sterilization and scale inhibition. The total bacterial count in the feed water must be controlled to below 100 CFU/mL, and the dosage of scale inhibitors should be adjusted based on the water quality, with a common range of 3–5 mg/L, mainly to prevent carbonate and sulfate scaling. Practical experience has shown that proper pretreatment can reduce membrane fouling rates by over 30%, significantly easing the pressure on subsequent operation and maintenance.

Simply doing proper pre-treatment isn’t enough; controlling the parameters during operation is like creating a “customized” living environment for the membrane, directly affecting its aging rate. Many people tend to adjust parameters based on experience, but in fact, there is an optimal range closely aligned with industry practices and manufacturer recommendations. It’s easy to remember and practical to use.

Temperature should be controlled between 20–30°C. According to the GWI 2025 actual data, for every 1°C increase in water temperature, the RO membrane’s water production increases by about 2.8%-3.2%, with an average of about 3%. However, once the temperature exceeds 35°C, the membrane aging speed accelerates significantly, and the chemical stability of the polyamide membrane decreases substantially.

The pH value should be maintained between 6 and 8 for optimal stability, especially for aromatic polyamide membranes, which perform best in this range. Extreme pH environments can easily damage the membrane structure. Operating pressure must strictly adhere to the rated upper limit. The design pressure for conventional brackish water RO membranes is 1.0–1.5MPa. Operating above this pressure will compress the membrane, making it difficult to recover flux later.

For recovery rate, a single-stage RO should be controlled between 50%-60%, while a two-stage system can increase it to 75%-85%, avoiding high salt concentrations on the concentrate side that could cause scaling.

It’s important to note that parameter optimization shouldn’t be done in isolation; a systemic approach is needed. For example, when handling high hardness water, don’t focus solely on recovery rate. By appropriately reducing the recovery rate and adjusting pH to 6.0–6.5, the risk of carbonate scaling can be effectively reduced. In winter, when water temperature is low and affects water production, pressure can be slightly increased, but it must not exceed the rated value to ensure both production needs and membrane protection. Many projects now have intelligent monitoring systems that can adjust these parameters in real-time, ensuring that membrane flux remains stable at over 85% of the design value, leading to more stable operation.

Membrane fouling is a gradual process, similar to how a filter in your home slowly accumulates dust. Timely and proper cleaning can effectively restore the membrane’s performance, but improper operation can shorten its lifespan. Many people don’t know when to clean the membrane, but there are clear, industry-standard guidelines: a 10%-15% decrease in standardized water production, a 10%-15% increase in transmembrane pressure (or operating pressure), or a 10%-15% drop in system desalination rate all signal that it’s time to start cleaning. Delaying this will cause the fouling layer to solidify over time, eventually leading to irreversible damage, and cleaning will no longer be effective.

hthrjt2017@gmail.com

hthrjt2017@gmail.com