In the past 20 years, more research has been carried out on ammonia nitrogen sewage treatment. At present, the most used technologies in China are: traditional biological denitrification method, ammonia blowing stripping method, breakpoint chlorination method, chemical precipitation method, ion exchange method, membrane method, etc.

01. Various nitrogen removal processes

1. Traditional biological denitrification

Traditional biological denitrification technology is completed by ammonia, nitrification, denitrification and assimilation. The traditional biological denitrification process is mature and the denitrification effect is better. However, there are disadvantages such as long process flow, large land area, frequent need for additional carbon sources, high energy consumption, and high cost.

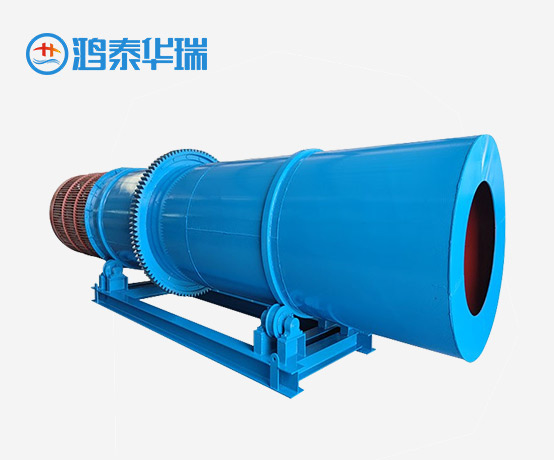

2. Ammonia blowing

The mechanism is to adjust the wastewater to alkaline, and then pass air or steam into the blow-off tower to blow out the free ammonia in the wastewater through gas-liquid contact. This method has a simple process, stable effect, strong applicability, and low investment. However, the energy consumption is large and there is secondary pollution.

NH4++ OH-= NH3 +H2O

OH- is generally provided by NaOH, which has a molecular weight of 40; Regardless of other factors, it is theoretically calculated that 2.86kg of NaOH is required to remove 1kg of NH4+, and the cost of removing 1kg of NH4+ is 5.72 yuan (blowing out ammonia without absorption) according to the calculation of 2.0 yuan/kg of industrial grade NaOH. The power consumption of blowing out is about 4 degrees/ton.

3. Ion exchange

The ion exchange method actually uses exchangeable ions on insoluble ionic compounds (ion exchangers) to exchange with other isomeric ions (NH4+) in the solution, so as to firmly adsorb NH4+ in wastewater on the surface of the ion exchanger to achieve the purpose of removing ammonia nitrogen. Although the ion exchange method has achieved certain results in removing ammonia nitrogen from wastewater, the amount of resin is large and it is difficult to regenerate, resulting in high operating costs and secondary pollution.

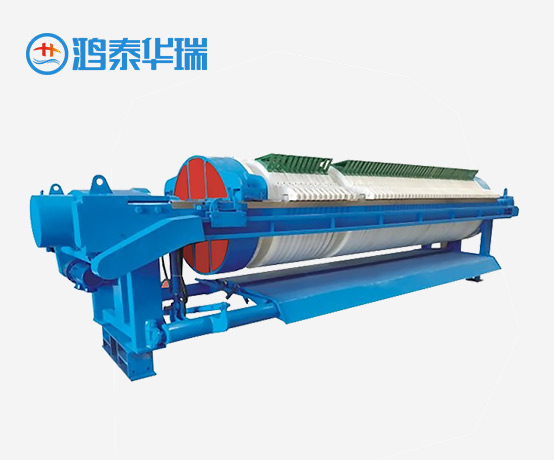

4. Membrane filtration

A method of ammonia nitrogen removal using the selective permeability of the membrane. This method is easy to operate, has high ammonia nitrogen recovery rate, and has no secondary pollution, but the investment cost is too high, and the requirements for the water quality of wastewater are too high, especially salinity.

5. Chlorine method at the breaking point

The breakpoint chlorination method is a chemical denitrification process in which excessive chlorine or sodium hypochlorite is added to oxidize ammonia nitrogen in wastewater into nitrogen. The treatment efficiency of this method can reach 90%~100%, and the treatment effect is stable and not affected by water temperature. However, the operating cost is high, and the by-products chloramines and chlorinated organic compounds will cause secondary pollution.

6. Magnesium ammonium phosphate precipitation method (struvite method)

Mg2+ and PO43- were added to the ammonia nitrogen-containing wastewater, and the three reacted to form MgNH4PO4·6H2O (MAP) precipitate. This method is simple in process, easy to operate, fast reaction, few influencing factors, and can fully recover ammonia to realize wastewater recycling. The main limitation of this method is that the dosage of precipitation agents is large, resulting in high treatment costs, and the use of precipitation product MAP needs to be further developed and promoted.

Mg2++ PO43-+ NH4+= MgNH4PO4

Mg2+ is generally provided by MgCL2, which has a molecular weight of 95; PO43 - is generally provided by NaH2PO4, molecular weight 145, regardless of other factors, theoretically calculated to remove 1kg NH4+ requires MgCL27.6kg, NaH2PO410.36kg, according to industrial grade MgCL22.5 yuan/kg, industrial grade NaH2PO43.0 yuan/kg, the cost of removing 1kg NH4+ is 50 yuan. Produce 18kg of magnesium ammonium phosphate precipitate (excluding crystalline water)

02. Advantages and disadvantages of various ammonia removal processes

03. Control conditions of the denitrification process

1. pH

A large number of studies have shown that the suitable pH of ammonia oxidizing bacteria and nitrite oxidizing bacteria is 7.0~8.5 and 6.0~7.5, respectively, and when the pH value is lower than 6.0 or higher than 9.6, the nitrification reaction stops. After a period of domestication, nitrifying bacteria can be carried out under low pH (5.5), but if the pH value suddenly drops, the nitrification reaction rate will drop sharply, and the nitrification reaction will also resume after the pH value rises and recovers.

The most suitable pH value for denitrifying bacteria is 7.0~8.5, at which the denitrification rate is higher, and when the pH value is lower than 6.0 or higher than 8.5, the denitrification rate will decrease significantly. In addition, pH also affects the final product of denitrification, when the pH value exceeds 7.3, the end product is nitrogen, and when the pH value is lower than 7.3, the end product is N2O.

The pH of the wastewater decreased by the depletion of the alkalinity in the wastewater during the nitrification process (7.14g of alkalinity in CaCO3 was consumed per 1g of ammonia nitrogen nitrification). On the contrary, the denitrification process will produce a certain amount of alkalinity to increase the pH value (3.57g of nitrate will be produced for every 1g of nitrate, calculated as CaCO3), but since the nitrification reaction and denitrification process are carried out in sequence, that is to say, the alkalinity produced in the denitrification stage cannot compensate for the alkalinity consumed in the nitrification stage. Therefore, to keep the denitrification system in optimal condition, the pH should be adjusted in time.

2. Temperature (T)

The suitable temperature range of nitrification reaction is 5~35°C, and in the range of 5~35°C, the reaction speed accelerates with the increase of temperature, and when the temperature is less than 5°C, the metabolic ability of nitrifying bacteria is seriously reduced and almost stops moving. In the simultaneous removal of COD and nitrification reaction system, when the temperature is less than 15°C, the nitrification reaction rate will decrease rapidly, and the inhibition of nitrate bacteria will be stronger.

The suitable temperature for denitrification reaction is 15~30°C, when the temperature is lower than 10°C, the denitrification effect decreases rapidly, and when the temperature is higher than 30°C, the denitrification rate also begins to decrease.

Studies have shown that the influence of temperature on denitrification rate is directly related to the type of reaction equipment and the level of load rate, and the effects of different temperatures on denitrification rate are also different under different carbon source conditions.

3. Dissolved oxygen (DO)

The nitrification reaction can only be carried out under aerobic conditions, and the concentration of dissolved oxygen not only affects the nitrification reaction rate, but also affects its metabolites. In order to meet the normal nitrification reaction, the concentration of dissolved oxygen in activated sludge should be at least 2mg/L, generally 2~3mg/L, and the biofilm rule should be greater than 3mg/L. When the concentration of dissolved oxygen is lower than 0.5~0.7mg/L, the nitrification reaction process will be limited.

The traditional denitrification process needs to be carried out under strict hypoxic conditions, because oxygen competes with electron donors and inhibits the synthesis and activity of nitrate reductase by microorganisms. However, under normal circumstances, there is an oxygen deficiency zone in the activated sludge biofloc, and denitrification can be carried out even if there is a certain amount of dissolved oxygen in the aeration tank. The results show that in order to obtain a better denitrification effect, the dissolved oxygen concentration of the mixture during the denitrification process should be controlled below 0.5mg/L for the activated sludge system. For biofilm systems, dissolved oxygen needs to be kept below 1.5 mg/L.

4. Carbon-to-nitrogen ratio (C/N)

In the denitrification process, C/N will affect the proportion of nitrifying bacteria in the activated sludge. Because nitrifying bacteria are autotrophic microorganisms and do not require organic matter in the metabolic process, the smaller the BOD5/TKN in the sewage, that is, the lower the concentration of BOD5, the greater the proportion of nitrifying bacteria, and the easier it is to carry out the nitrification reaction.

Ammonia nitrogen is the main matrix of nitrification, which should be maintained at a certain concentration, but when the ammonia nitrogen concentration exceeds 100~200mg/L, it will inhibit the nitrification reaction, and its inhibition degree increases with the increase of ammonia nitrogen concentration.

The denitrification process requires sufficient organic carbon sources, but different types of carbon sources will also affect the denitrification rate. Denitrifying carbon sources can be divided into three categories: the first is easily biodegradable soluble organic matter; the second category is slowly degradable organic matter; The third category is cellular material, where bacteria use cellular components for endogenous nitrification. Among the three types of substances, the first type of organic matter as a carbon source has the fastest reaction rate, and the third type has the slowest reaction rate.

Some studies believe that when BOD5/TKN≥4~6 in wastewater, the carbon source can be considered sufficient and there is no need to add carbon sources.

5. Sludge age (SRT)

Sludge age (residence time of biosolids) is the control goal of wastewater nitrification management. In order for the nitrifying bacterial flora to survive in a continuous flow system, the SRT of the system must be greater than the specific growth rate of autotrophic nitrifying bacteria, and too short a mud age will lead to the loss of nitrifying bacteria or a decrease in the nitrification rate. In the actual denitrification project, the age of the sludge should be greater than the actual SRT. Studies have shown that for activated sludge denitrification, the age of sludge is generally not less than 15 days. Longer sludge age can increase the nitrification ability of microorganisms and reduce the inhibition of toxic substances, but it will also reduce the activity of sludge.

6. Internal return ratio (r)

The function of internal reflux is to supply nitrate nitrogen to the denitrification reactor, so that it can be used as an electron acceptor for denitrification, so as to achieve the purpose of denitrification. The value of the cycle ratio is related to the desired effect and the type of reactor. Some data show that the cycle ratio is less than 50% and the denitrification rate is very low; The denitrification rate was below 200%, and the denitrification rate increased significantly with the increase of cycling ratio. After the internal reflux ratio is higher than 200%, the denitrification efficiency increases slowly. Under normal circumstances, for wastewater with low ammonia nitrogen concentration, the return ratio is 200%~300% is the most economical.

7. Redox potential (ORP)

Theoretically, both hypoxic and anaerobic segments have zero DO, so it is difficult to describe them in DO. According to research, the ORP value of the anaerobic section is generally between -160~-200mV, the ORP value of the aerobic section is generally between +180mV, and the ORP value of the anoxic section is between -50~-110mV, so ORP can be used as the control parameter of nitrogen removal operation.

8. Inhibitory substances

Some organic matter, some heavy metals, cyanide, sulfur and derivatives, free ammonia and other harmful substances will inhibit the normal progress of nitrification reaction when they reach a certain concentration. The permissible concentration of free ammonia inhibition: nitrite (Nitosomonas) is 10~150mg/L, and nitrate (Nitrobacter) is 0.1~1mg/L. The main reasons for organic matter inhibition of nitrification reaction are: first, when the concentration of organic matter is too high, the concentration of heterotrophic microorganisms in the nitrification process will greatly exceed the concentration of nitrifying bacteria, so that the nitrifying bacteria cannot obtain enough oxygen and affect the nitrification rate; Second, some organic matter has a direct toxic or inhibitory effect on nitrifying bacteria.

9. Nitrogen conversion conditions in the process of biological denitrification

The biological denitrification process includes ammonia oxidation, nitrification, nitrification and denitrification, and the degradation and carbonization process of organic matter is also completed at the same time. Considering various factors (such as strains and their rate of appreciation, dissolved oxygen, pH, temperature, load, etc.) can effectively reduce and improve the overall process of biological denitrification.

10. Other factors influence

The biological denitrification system involves anaerobic and hypoxic processes, does not require oxygen supply, but must keep the sludge in suspension, stirring is necessary, the power required for stirring is generally 12~16W/m3 for vertical agitators and 8W/m3 for horizontal agitators.