Working in industrial wastewater operations, the most unforgettable experience was receiving a call from the workshop at 2 AM: the aeration tank foam was overflowing, the online monitoring instrument was flashing red, and the COD shot up to 2000mg/L, with the environmental inspection team waiting in the park. After experiencing this kind of "life-or-death moment" more than 30 times, I compiled this emergency troubleshooting guide, covering high-frequency issues in industries such as chemicals, pharmaceuticals, and electroplating, along with the latest policy red lines and practical tips. After reading it, you’ll at least be able to save yourself from losing millions in fines.

Key Points to Note

Global environmental regulations are entering a period of strict management. The United Nations Environment Programme (UNEP) will release the "Global Industrial Wastewater Treatment Action Guide" in 2025, which will set unified global pollutant control requirements. The EU's Industrial Emissions Directive (IED) revised version for 2024 will raise the fine cap for exceeding emissions to 4% of a company's annual turnover. The UN’s "Sustainable Development Goal 6 Mid-term Progress Report" shows that only 27% of global industrial wastewater is safely treated, while 38% undergoes basic treatment before being discharged. Industry data is even more alarming: the annual failure rate of global industrial wastewater treatment equipment is 18%, and 68% of companies have exceeded emission standards due to equipment failures, with the average single economic loss (including fines, shutdowns, and rectifications) exceeding 2 million USD. In developed countries, fines account for over 60%, while in developing countries, the loss due to production shutdowns is even higher.

Three Major High-Frequency Failures and Emergency Responses: Stabilize the Situation Within 30 Minutes

The most common issues during operations are water quality exceeding standards, equipment shutdowns, and abnormal energy consumption. Mastering the following methods can help control most failures within one hour.

1. Water Quality Exceeding Standards: Prioritize "Source Control + Emergency Response" to Avoid a Chain Reaction

COD/BOD, ammonia nitrogen, and total phosphorus exceedances account for 70% of all water quality problems. The core of emergency response is "stop losses first, then trace the source."

If COD suddenly spikes (e.g., from 500mg/L to 2000mg/L), immediately stop inflow or switch to an accident adjustment pool. Add powdered activated carbon (10-20g/L) to adsorb toxic substances and adjust the aeration tank DO to 2-4mg/L. Supplement with urea and potassium dihydrogen phosphate in a C/N/P ratio of 100:5:

- A Southeast Asian plant of a multinational chemical company once caused a biochemical system collapse due to illegal discharge of high-concentration wastewater, with COD exceeding the limit by four times. They were fined 3% of their annual turnover (about 20 million USD) by local environmental authorities and required to carry out wastewater treatment system rectifications in all global factories. They eventually restored compliance within 72 hours using this emergency method, avoiding a global production shutdown crisis.

- Ammonia Nitrogen Exceedance (above 1.5mg/L, globally accepted standard value) is usually due to inhibition of the nitrification process. Quick solution: adjust the pH of the aerobic tank to 7.5-8.5, increase aeration by 30%, and ensure DO ≥ 3mg/L. If the water temperature is below 15°C in winter, add nitrifying bacteria agents and extend the sludge age to over 20 days. Note that both the revised EU IED and UNEP guidelines require ammonia nitrogen to be controlled by both daily average and instantaneous values, with the instantaneous value not exceeding 1.3 times the daily average. Over 80% of countries worldwide have adopted this standard.

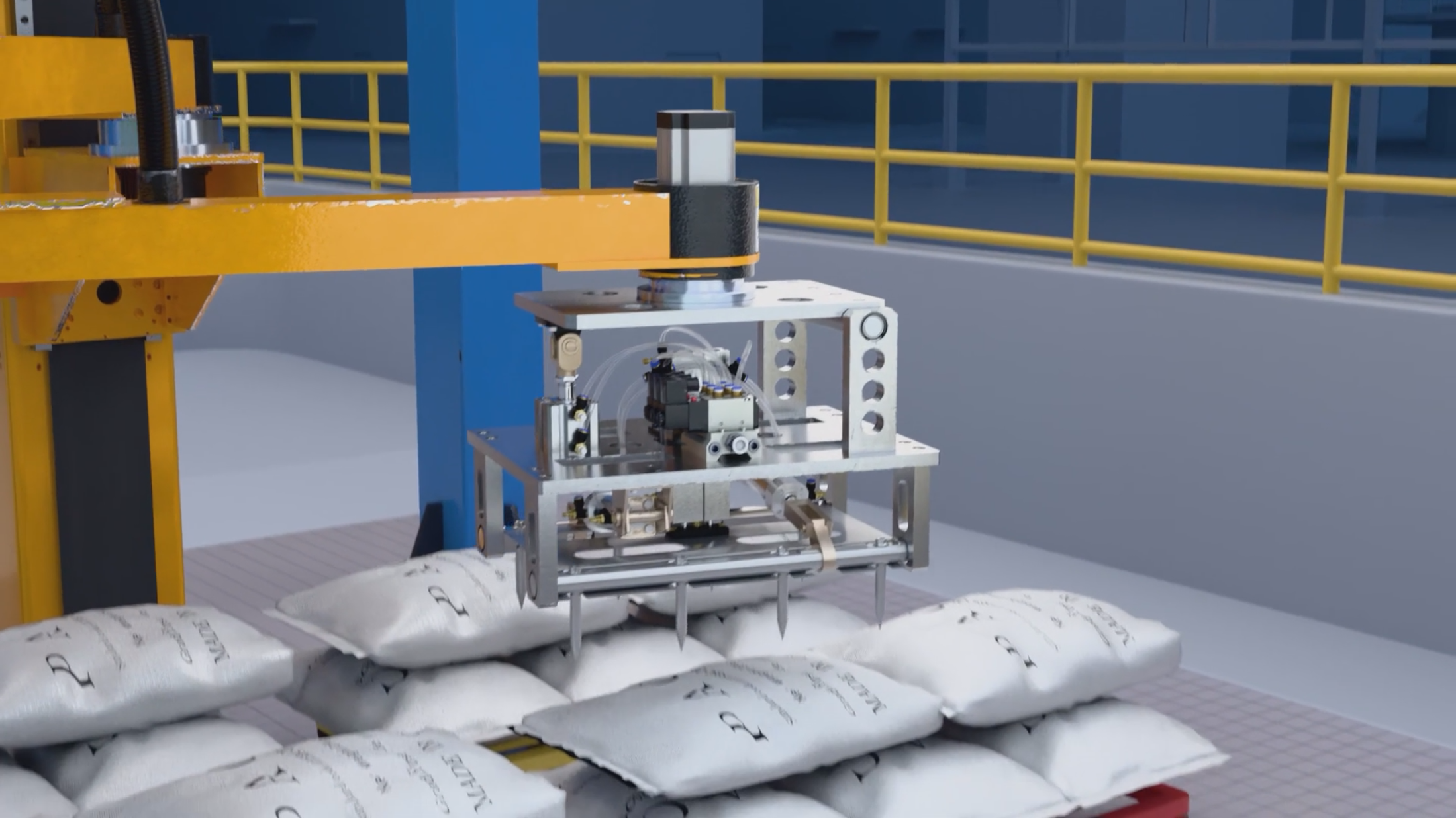

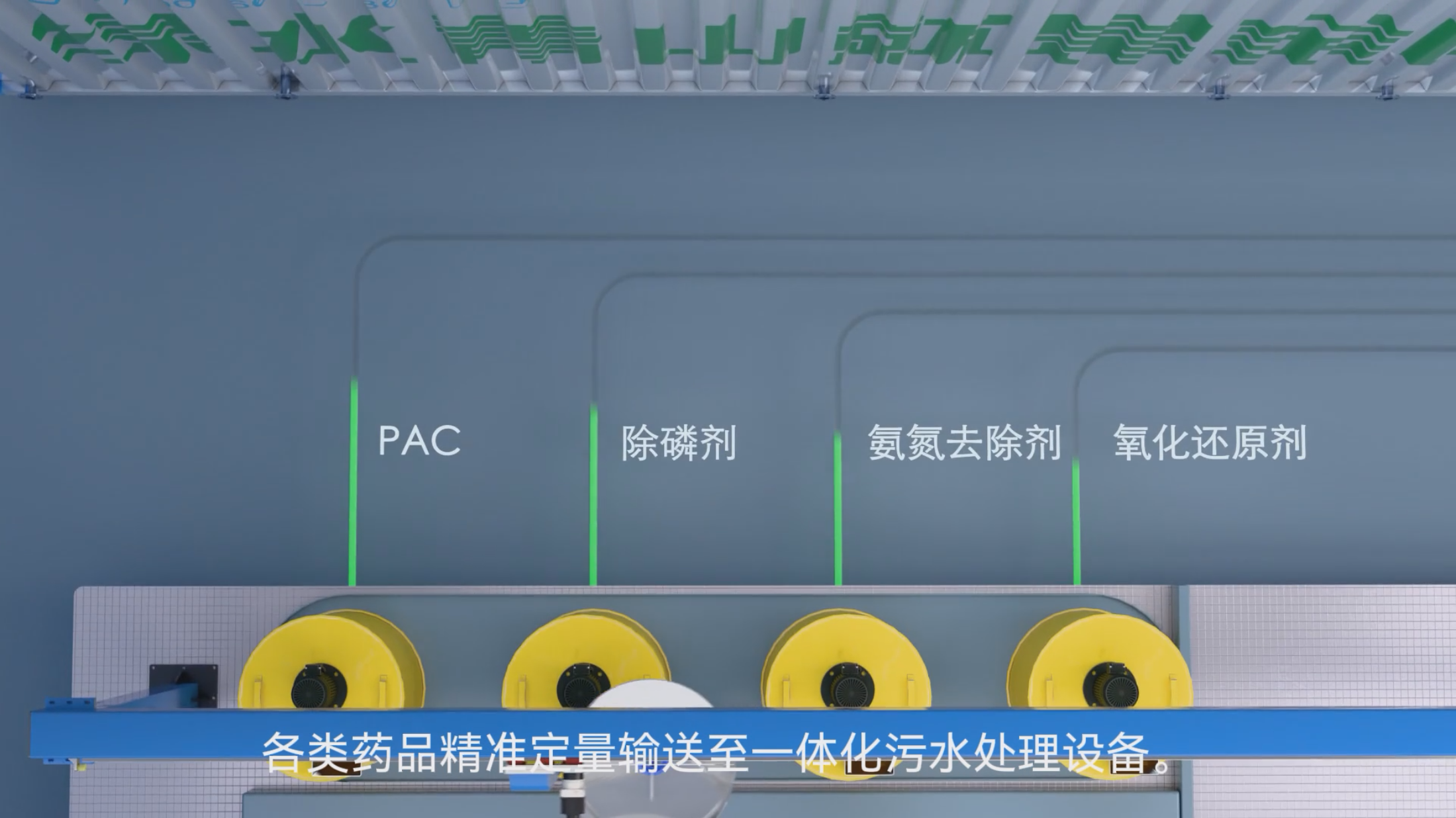

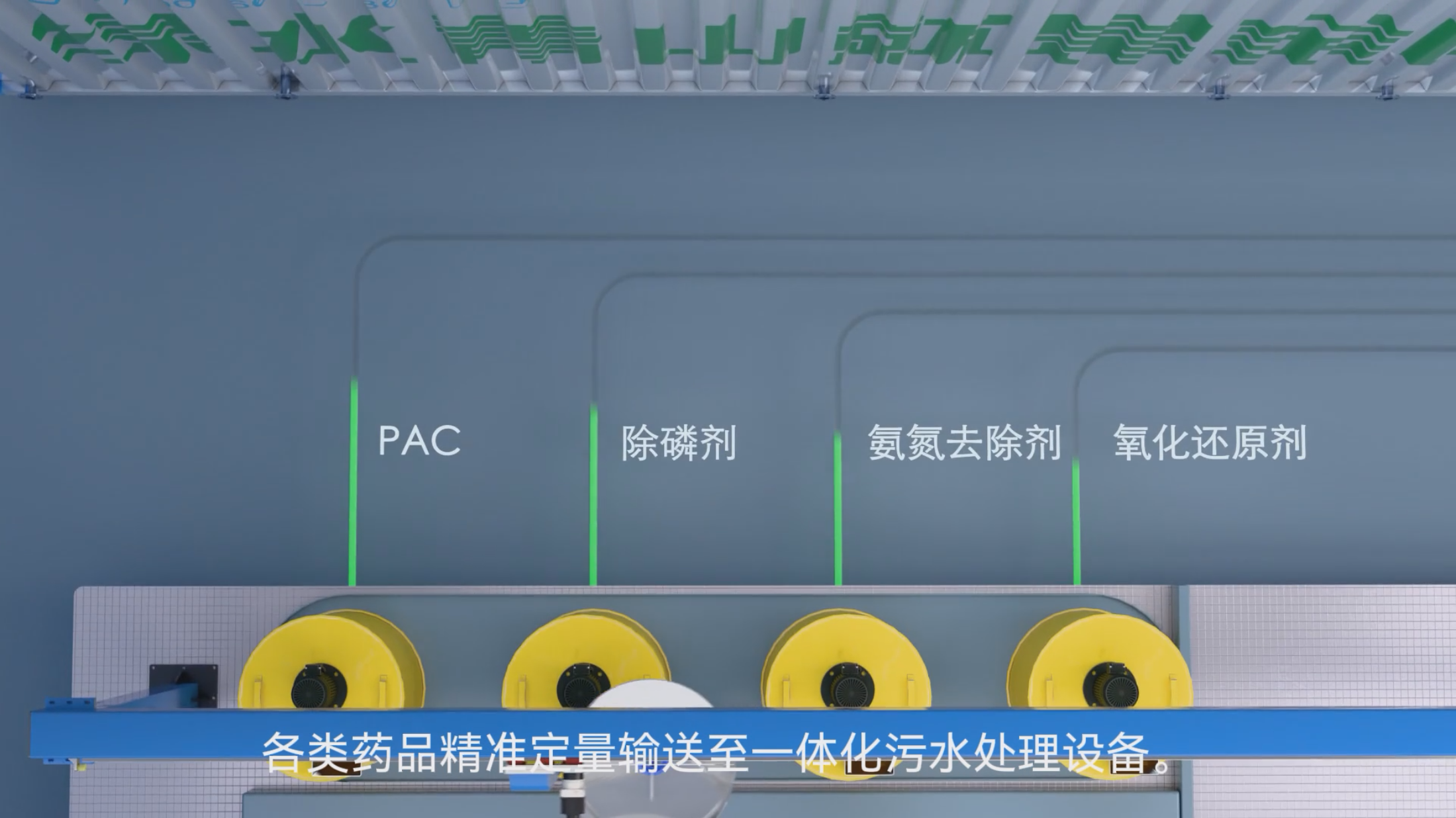

- Total Phosphorus Exceedance (above 0.3mg/L, SDG6 core water quality improvement limit) has two situations: If biological phosphorus removal fails, extend the anaerobic phase retention time to 3 hours and add sodium acetate as a carbon source. If chemical phosphorus removal is insufficient, immediately increase the PAC dosage (according to the molar ratio of phosphorus to aluminum ions 1:2), and control the reaction pH between 6-8. According to UN data, industrial discharge accounts for 45% of global eutrophication events due to total phosphorus exceedance, with 70% originating from treatment system failures.

2. Equipment Failure: Switch to Backup First, Then Check the Root Cause

Water pump, aeration, and dosing system failures are high-risk areas in operation and maintenance, with 90% of equipment issues being quickly located through "visual inspection, listening, and touch."

Water pump won't start: First, check if the power supply is missing a phase, and if the motor's insulation resistance meets standards (≥1MΩ). If the impeller is clogged, disconnect the power, disassemble the pump to clean it, and ensure the air inside the pump is fully purged before restarting to avoid air lock.

Aeration head clogging causes a sharp drop in DO levels. Clean it by flushing with high-pressure water or soaking in 5% oxalic acid for 2 hours. In emergencies, switch to a backup fan to avoid system failure due to lack of oxygen.

MBR membrane components are consumables. If the transmembrane pressure difference exceeds 30 kPa and water production decreases by 50%, stop water production immediately for chemical cleaning: Use a 0.5% sodium hypochlorite solution for organic contamination and soak for 24 hours, or clean with 2% citric acid for inorganic contamination. After cleaning, flux recovery can be over 80%. Note: If membrane system failure is delayed for more than 24 hours, the replacement cost will triple.

3. Abnormal Energy Consumption: Quick Cost Reduction, Avoid Waste

Electricity consumption accounts for 45%—65% of wastewater treatment operational costs globally. According to the International Energy Agency (IEA) 2025 data, the average energy consumption for industrial wastewater treatment is 0.85 kWh/ton, with inefficient operators reaching over 1.2 kWh/ton. If energy consumption exceeds 0.9 kWh/ton, immediately check the operation parameters of the fan and water pump: excessive aeration increases energy consumption by 20%—30%. Aeration can be automatically adjusted via online DO monitoring, and during low-night loads, aeration can be reduced by 50%. For water pumps, adjust the frequency of the variable frequency drive and optimize the return ratio to 50%—80%. Global practices show that this operation can save 15%—25% on electricity costs monthly, with some Western companies reducing it by up to 30%.

II. Industry-Specific Pitfall Guide: Addressing Special Issues

Wastewater characteristics vary greatly across industries, and blindly applying generic methods can cause issues. These 4 industries require special attention:

Chemical Industry: Globally, 72% of chemical industry wastewater contains toxic substances such as heavy metals and cyanides, making it one of the most challenging industrial wastewater treatment sectors. If microorganisms are poisoned, immediately add activated carbon to adsorb toxins and "shut-off aeration" for 24 hours. Strengthen pre-treatment to ensure that incoming COD fluctuations do not exceed 20% of the design value. In 2024, a multinational chemical company’s European factory suffered biochemical system failure due to insufficient pre-treatment, causing wastewater to discharge directly into a tributary of the Rhine River, resulting in a fine of 4% of its annual revenue (about $32 million) and requiring a $120 million investment to renovate the treatment system, with 28 days of production downtime.

Pharmaceutical Industry: WHO data shows that antibiotic residue levels ≥0.05 mg/L in pharmaceutical wastewater can inhibit microbial activity, much lower than the previous 0.1 mg/L standard in some countries. In emergencies, use specialized detoxifiers; long-term solutions involve cultivating resistant bacteria and adopting a hydrolysis-acidification + MBR combined process. Global practices show this method can increase biodegradability of pharmaceutical wastewater by 30%—40%, with mainstream pharmaceutical companies in Europe and the U.S. adopting it. This process improves compliance by 25 percentage points over traditional methods.

Electroplating Industry: In global electroplating wastewater, complexed heavy metals account for 63% of excess concentrations, and conventional chemical precipitation methods struggle to remove them. If total chromium exceeds 0.3 mg/L (EU RoHS directive limit) or total nickel exceeds 0.05 mg/L (global special emission standard), complex bonds need to be broken using Fenton’s reagent (Fe²⁺+H₂O₂), then adjust pH to 8-9 and add heavy metal capture agents. Over 90% of compliant electroplating enterprises globally have adopted a "complex-breaking + chemical precipitation" two-stage treatment process, achieving a compliance rate of over 99%.

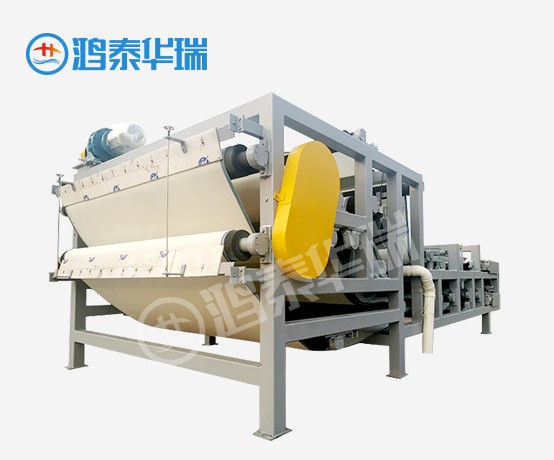

Food Industry: Globally, food processing wastewater has an organic matter concentration of 3000—12000 mg/L, with oil content 3-5 times higher than regular industrial wastewater, and the sludge bulking rate is 40% higher than other industries. When the SVI exceeds 150 mL/g, add PAC/PAM to improve sedimentation and increase sludge dewatering, reducing sludge age to 10 days. Also, strengthen oil separation pretreatment to prevent oil from wrapping the sludge. According to a World Bank report, food enterprises with improved pretreatment reduce wastewater system failure rates by 55%.

3. Policy Red Lines + Preventive Techniques: Reducing Failures at the Source

Global environmental protection regulations have entered the "whole process control + multinational collaboration" stage. In line with the United Nations SDG6 (clean water sources and public health facilities) targets and UNEP's "Global Industrial Wastewater Treatment Action Guidelines," implementing these three points can reduce failure rates by over 50%: By 2030, the global industrial wastewater safe treatment rate must increase to 70%, and the industrial water reuse rate must rise by 18 percentage points compared to 2020. This goal has been jointly recognized by 193 UN member states.

- Establish an Early Warning System: Install smart sensors at the water inlet, biological tanks, and main discharge points to set alarm thresholds for parameters like COD, pH, etc. (e.g., if COD exceeds 150% of the design value, trigger a yellow alert), with a response time ≤30 minutes.

- Regular Equipment Maintenance: Follow the principle of "daily cleaning, weekly inspection, monthly maintenance." Lubricate fan bearings once a month, clean aeration heads every quarter, chemically clean membrane components every six months, and perform a 30-minute test run of backup equipment every week.

- Never Cross the Compliance Bottom Line: Over 180 countries worldwide have implemented pollution discharge licensing systems, requiring companies to monitor core indicators (COD, ammonia nitrogen, pH, etc.) daily and upload data to regional environmental platforms. Regarding industrial water reuse rates, the EU aims for 90% by 2030, North America for 88%, and developing countries have an average target of 85%. Companies failing to meet these standards will face penalties such as capacity restrictions and trade barriers, not just fines.

The core of industrial wastewater operations and maintenance has always been "preventing problems before they arise, with emergency procedures in place." Whether it's water quality exceeding standards, equipment failures, or energy consumption abnormalities, only by mastering emergency techniques, strictly adhering to global environmental policies, and ensuring routine preventive maintenance can economic losses and compliance risks be avoided. For industries like chemicals, pharmaceuticals, electroplating, and food processing, targeted operation strategies and standardized processes are the key to ensuring the stable operation of treatment systems. Only by respecting professionalism and paying attention to details can we achieve the coordinated development of industrial production and water environmental management under the trend of strict global environmental regulation.

hthrjt2017@gmail.com

hthrjt2017@gmail.com