- release date: 2022-08-30 22:19:42

- author: Hongtai Huairui

- Reading: 3754

key words: Huangxiao River, Railway Bridge, Purification Water Plant

Hongtai Huarui Technology Group welcomes your visit. We have been dedicated to the environmental protection and governance industry for over a decade! We look forward to a cooperation with you!

key words: Huangxiao River, Railway Bridge, Purification Water Plant

project overview

In order to effectively solve the problem of sewage overflow pollution at the beginning of the Huangxiao River Open Channel in Wuhan City during the dry season, pollution control is carried out from the source of the open channel, while taking into account the control of combined overflow pollution in rainy days. According to the superior plan, a strip plot on the east side of the open channel is selected to build a 10,104 m3/d water purification plant to solve the regional urban sewage problem.

Due to the dense residential areas and large-scale business districts nearby, the land for public facilities construction is limited in area and in strip form. Taking into account various factors such as effluent quality and impact on the surrounding environment, the design determines to adopt a fully underground sewage plant. Except for TN at 15 mg/L and SS at 10 mg/L, other main indicators of effluent water quality comply with the surface Class IV water quality standard. The treated tail water from the sewage plant is discharged into the Huangxiaohe open channel as ecological water replenishment for the open channel.

Design basis

Underground sewage treatment plants need to consider the layout of sewage treatment facilities and auxiliary facilities, and set up two independent sewage treatment lines according to convention, and integrate these two types of facilities. This needs to be combined with the land use conditions, as well as the space required for installation and construction, inspection and maintenance, as well as the requirements of ventilation and deodorization, lighting and fire protection.

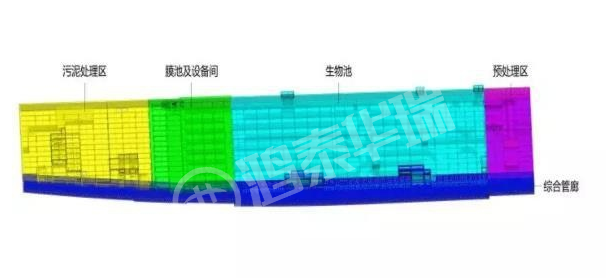

The land use area given by the builder is a strip plot about 500 m long and 80 m wide, with railways in the south, large business districts in the west, and elevated roads in the east, and limited land use conditions. The builder requested to arrange an underground sewage treatment plant with a treatment scale of 10×104 m3/d, and discharge the treated tailwater into the nearby open channel as ecological water replenishment. Based on the above boundary conditions, the layout of the underground sewage treatment plant treatment workshop is determined after optimization and design, as shown in Figure 2.

Design principles

Underground sewage treatment plants need to consider the layout of sewage treatment facilities and auxiliary facilities, and set up two independent sewage treatment lines according to convention, and integrate these two types of facilities. This needs to be combined with the land use conditions, as well as the space required for installation and construction, inspection and maintenance, as well as the requirements of ventilation and deodorization, lighting and fire protection.

The land use area given by the builder is a strip plot about 500 m long and 80 m wide, with railways in the south, large business districts in the west, and elevated roads in the east, and limited land use conditions. The builder requested to arrange an underground sewage treatment plant with a treatment scale of 10×104 m3/d, and discharge the treated tailwater into the nearby open channel as ecological water replenishment. Based on the above boundary conditions, the layout of the underground sewage treatment plant treatment workshop is determined after optimization and design, as shown in Figure 2. The whole sewage treatment workshop is about 282 m long and 64 m wide, and the workshop is mainly divided into two floors, the upper layer is the equipment operation layer and the driveway, and the lower layer is the structure layer and pipe gallery. The upper layer is about 6.6 m high, and the lower layer is about 7.0 m high. The thickness of the top cover of the whole workshop is more than 1.6 m; The lower part of the workshop is about 15.4m away from the deepest part of the design ground (the inner bottom of the floor plate of the biochemical tank and the emergency overflow pumping room), and the other part is about 9.4 m~13.4 m underground.

The pretreatment area is mainly fine grille, membrane grille and aerated sand settlement area, including the grid slag treatment area, and the utilization of the lower space of the fine grille pool is considered vertically as an air compressor and other equipment room. The space between the pretreatment area and the biochemical treatment area is also used as a water tank and equipment room.

The biochemical treatment area is the main A2O process area, which is the largest buried depth in terms of structure and vertical design, and the whole is pot bottom-shaped, and the key is the overflow and drainage of the biological tank, including the backwash drainage of the membrane tank. In order to reduce the land occupation, combined with the setting of the road on the first floor of the pipe gallery, the design incorporates the backwash drainage of the membrane pool and the overflow drainage of the structure into the drainage pump room and overflow pump room at the bottom of the pipe gallery, and then the pressure of the pump room is transported to the pretreatment inlet end. In this design, the deodorization facility is placed on the roof of the biochemical tank, making full use of the space on the roof of the biological tank.

The equipment and dosing room include MBR water production pump, blower room, power distribution room, dosing room, etc., forming an auxiliary comprehensive workshop; The sludge treatment area includes sludge dewatering room, mud storage, disinfection room, etc. The dosing room adopts the liquid agent ground discharge method, and the agent is connected to the dosing room through the discharge pump. After centrifugal concentration and dehydration, the sludge is collected and transported for disposal through the underground passage of the pipe gallery. The underground sewage plant only has a comprehensive building and a post station (above-ground landscape support) arranged outside the treatment workshop.

The sewage treatment workshop covers an area of about 1.8 hm2, considering the area of the total land use red line of above-ground landscape and supporting facilities is about 2.91 hm2, according to the requirements of the sewage treatment plant for the land use index in the "Construction Standards for Urban Wastewater Treatment Projects", the land area index per ton of water for secondary treatment and deep treatment is 0.8 m2, and the underground sewage treatment plant covers only 36.4% of the land area (8 hm2) of conventional surface sewage treatment plants of the same scale.

Source of pollution

Urban domestic sewage

Processing technology

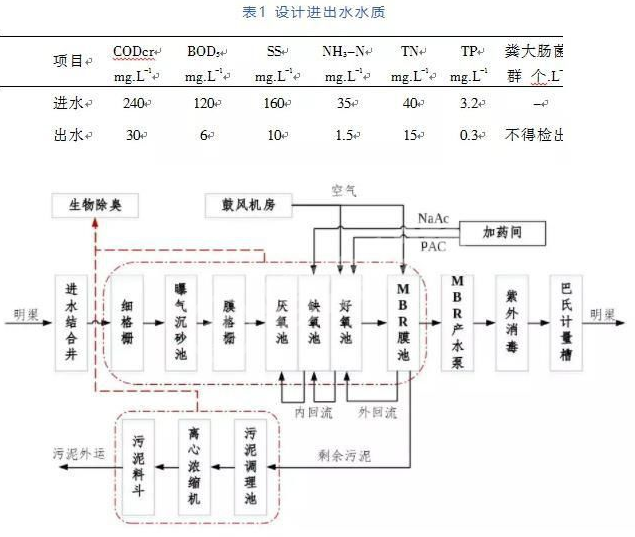

Referring to the influent water quality of the nearby sewage treatment plant and the effluent requirements of local construction units, the requirements of the inlet and outlet water quality of this project are determined (see Table 1), the secondary biological treatment process adopts the nitrogen and phosphorus removal process, and the activated sludge method applied to urban sewage treatment includes A2/O series, oxidation ditch series and SBR series. The biofilm method includes BAF and MBBR processes; The MBR process is also a new type of wastewater treatment process. Considering the actual situation around the beginning of the open channel near the project, the fluctuation of combined sewage water quality, and combined with the use of tailwater as ecological water replenishment, the process flow of the sewage plant is determined as shown in Figure 1.

The process adopts multi-point water inlet, and water inlets are provided in both the anaerobic and hypoxic zones to solve the problem of insufficient carbon source in the hypoxic area. The A2O biochemical tank mixture adopts segmented reflux, the anaerobic tank mixture is returned to the anaerobic tank to achieve anaerobic phosphorus release, the aerobic tank mixture is returned to the anoxic tank to achieve nitrification liquid reflux, and the remaining sludge in the membrane tank is returned to the aerobic tank. The ratio of internal and external return of the biochemical tank can be flexibly controlled according to the influent water quality, which can maximize the use of carbon sources, improve the nitrogen removal rate and the ability to resist dynamic changes in water quality in the rainy season.

In order to reduce the floor area and improve the effluent water quality, the slurry water separation of this process is completed by the MBR membrane of the deep treatment section, because the sewage treatment workshop adopts the whole buried setting, the structural form adopts a box, and the structures are covered to facilitate odor collection and treatment.

Handling indicators

The design scale of the Huangxiaohe Railway Bridge Underground Water Purification Plant is 10×104m3/d, using A2O+MBR as the core biological treatment combination process, the design effluent except for the limit concentrations of TN and SS of 15 mg/L and 10 mg/L respectively, the other main effluent water quality meets the surface water class IV water standard in the "Surface Water Environmental Quality Standard" (GB 3838-2002), and the treated tailwater is discharged into the Huangxiao River open channel as ecological water replenishment, and the sewage treatment plant is currently under construction.

In order to facilitate excavation support, foundation treatment and anti-floating design, the overall layout of the box should try to set up structures with similar buried depths as much as possible to achieve the same elevation and common floor plate, so as to avoid staggered elevations. In addition, from the perspective of operation and maintenance, it is necessary to focus on the overall design of lighting, ventilation and fire protection, which can effectively save operating energy consumption and ensure the safety of sewage treatment plant operation.

Above-ground and underground sewage plants have the same function, but there are differences in design focus. Secondary factors in the design of above-ground sewage plants, such as the lifting and installation of equipment limited by space and height, and the lighting and ventilation and deodorization have become the primary considerations in the design of underground sewage plants. Especially for deodorization and fire protection of underground sewage plants, in order to save the power of deodorization equipment, the deodorization device should be set up near the unit with the largest deodorization air volume to reduce the investment and operating costs of air ducts. In order to ensure fire safety, areas with dense personnel activities should be arranged as centrally as possible, rather than scattered.

The total investment of this project is about 600 million yuan, and the investment in tons of water is about 6,000 yuan/m3 of sewage, which is 3,000 yuan/m compared with the construction cost of conventional above-ground sewage treatment plants3The amount of wastewater has nearly doubled, so when using an all-underground wastewater treatment plant, it is necessary to weigh the relationship between the surrounding impact and the investment cost.

Previous Article:Smart and environmentally friendly toile...

Next Article:Papermaking wastewater reuse and treatme...

Environmental Protection Information

Selected Recommendations

Recommended Products